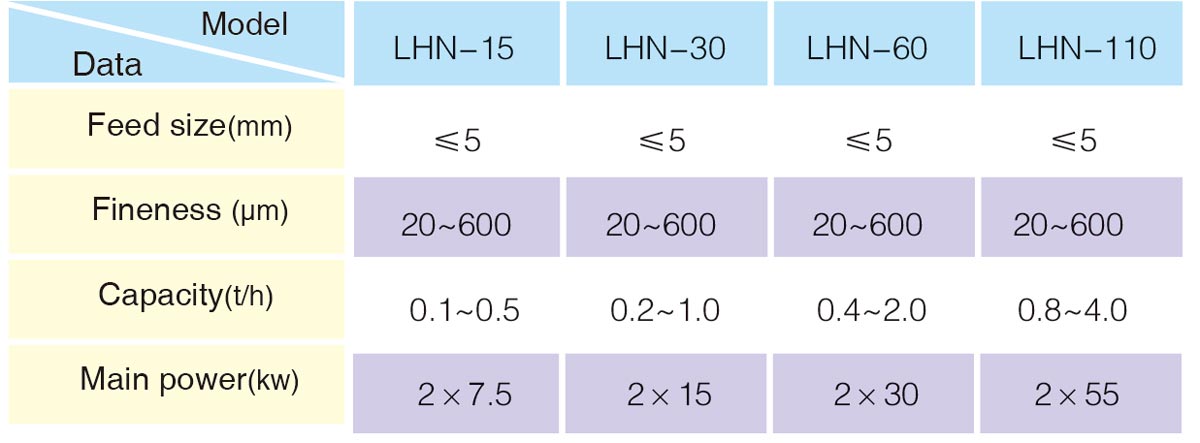

Features

1. LHN pin mill can use the pin bars with different structures according to the properties of materials. 2. After the special wear-resisting processing, the pin bar has long service life. 3. LHN pin mill can selectively use the one-way clutch plate or two-way clutch plate according to the material processing fineness. 4. LHN pin mill adopts the double quick-opening structure, which is convenient for cleaning. 5. LHN pin mill uses the clutch drive that is of high energy-conversion efficiency. And also, the sealing designed bearing has the advantages of reliability and long service life. 6. It can process the materials whose Mons' hardness scale is less than 3.5 materials. The processing fineness is adjustable and the size of finished product can be 20um below.

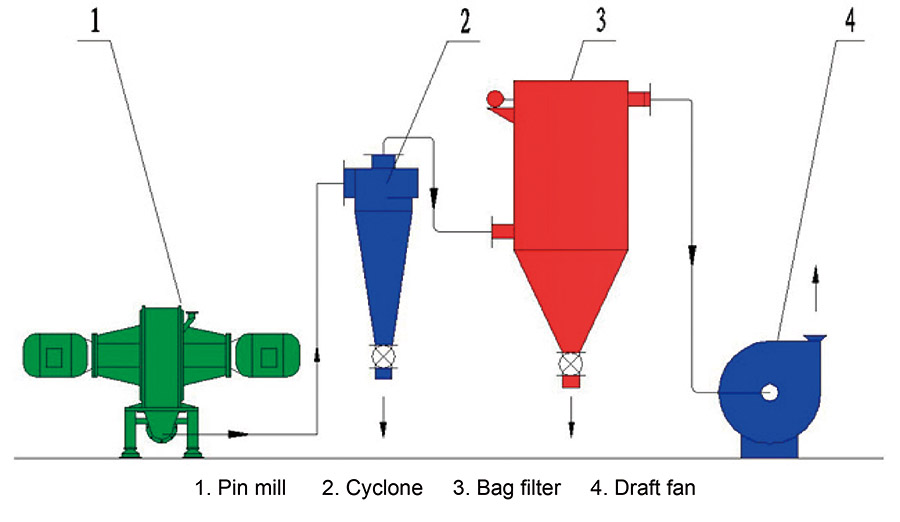

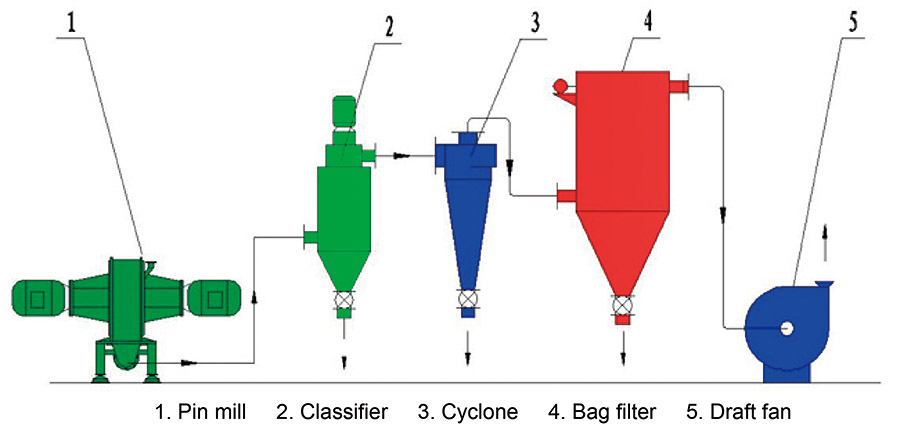

Technological Process

Applications 1. LHN pin mill is the best choice for processing the oily materials, viscous materials, heat-sensitive materials and various other materials. ① it can process cocoa beans crushing, condiments, traditional Chinese medicines and various other food and medicine materials. ② it is used for processing chemical materials with high stickiness such as dyes, paints, and so on. 2. LHN pin mill can be injected with the liquid nitrogen or cold air to smash the strong-toughness materials such as Nylon, rubber, and various other materials.

Applications 1. LHN pin mill is the best choice for processing the oily materials, viscous materials, heat-sensitive materials and various other materials. ① it can process cocoa beans crushing, condiments, traditional Chinese medicines and various other food and medicine materials. ② it is used for processing chemical materials with high stickiness such as dyes, paints, and so on. 2. LHN pin mill can be injected with the liquid nitrogen or cold air to smash the strong-toughness materials such as Nylon, rubber, and various other materials.